Revolutionizing Business Efficiency with Cutting-Edge Electronics and 3D Printing Technologies: The Role of Mobile Cement Silos

In today’s rapidly evolving industrial landscape, businesses are relentlessly seeking innovative solutions to improve productivity, reduce costs, and enhance safety measures. Among these groundbreaking advancements, industries such as construction, manufacturing, and logistics are increasingly turning to electronics and 3D printing technologies. A prime example of this synergy is the development and deployment of mobile cement silos, which embody the confluence of technological innovation and practical application. In this comprehensive article, we explore how these cutting-edge technologies are transforming traditional business models, especially within the realm of construction and material handling, thereby setting a new standard for industry excellence.

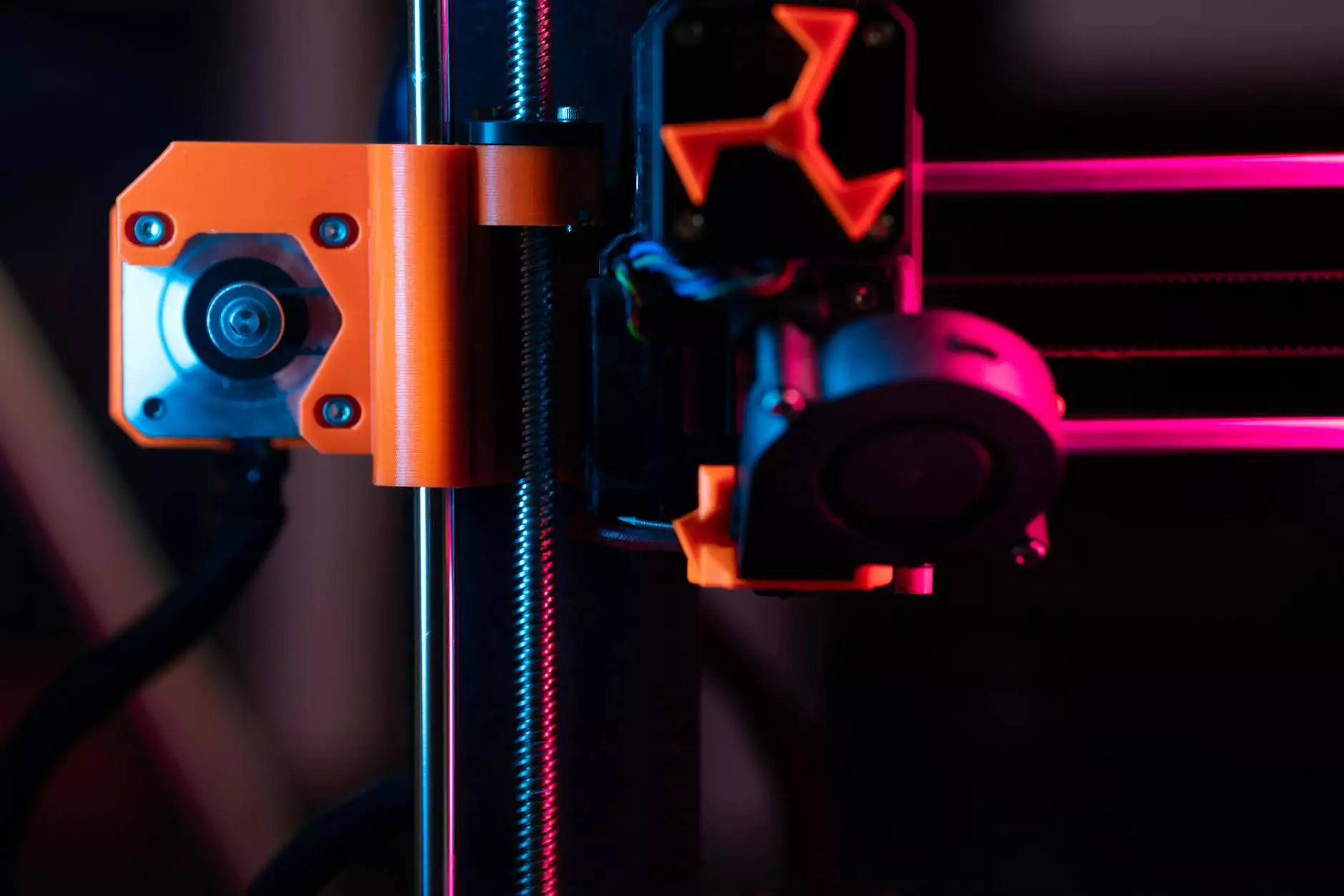

Understanding the Role of Electronics and 3D Printing in Modern Business

The integration of advanced electronics and 3D printing into industrial processes marks a pivotal shift toward automation, customization, and smart manufacturing. These technologies contribute to nimble production cycles, improved quality control, and significant cost savings. Key benefits include:

- Enhanced Precision and Quality: With embedded sensors and automation controls, electronics ensure consistent quality in manufacturing.

- Rapid Prototyping and Customization: 3D printing allows for quick design alterations and the creation of tailored components directly from digital models.

- Operational Efficiency: Automation reduces manual labor, accelerates production timelines, and enables round-the-clock operations.

- Data-Driven Decision Making: IoT-enabled electronics provide real-time analytics, facilitating smarter business strategies.

- Sustainable Practices: Both technologies enable waste reduction and energy efficiency, aligning with environmentally responsible initiatives.

How 3D Printing and Electronics Drive Innovation in the Construction Sector

The construction industry is experiencing a renaissance powered by these technological advancements. One of the most promising innovations is the development of mobile cement silos integrated with smart electronics and 3D printing components. These innovations are disrupting traditional paradigms by offering:

Enhanced Mobility and Flexibility

Conventional cement silos are bulky, stationary structures that limit logistical versatility. In contrast, mobile cement silos equipped with electronic control systems and fabricated using 3D printing techniques are lightweight, portable, and highly adaptable. This mobility allows construction companies to deploy cement storage precisely where it is needed, optimizing material supply chain workflows and reducing delays.

Smart Monitoring and Maintenance

With integrated electronic sensors, modern mobile cement silos continuously monitor contents, pressure levels, temperatures, and structural integrity. This real-time data facilitates predictive maintenance, minimizes downtime, and ensures safety compliance. The ability to remotely track silo status empowers firms to make timely decisions, thereby enhancing overall operational efficiency.

Customization and Rapid Deployment

Thanks to 3D printing technology, manufacturers can produce customized silo components tailored to specific project requirements rapidly. This flexibility accelerates deployment timelines and allows for swift modifications in silo design to accommodate changing project scopes or site constraints.

Technical Innovations in Mobile Cement Silos: What Sets Them Apart?

Contemporary mobile cement silos are marvels of engineering, combining traditional construction with the latest electronic control systems and 3D printed parts. Here are some key technical features that define their superiority:

- Integrated IoT-enabled Control Panels: Facilitate remote operation, status monitoring, and data logging with user-friendly interfaces.

- Lightweight yet Durable Materials: 3D printing allows for the production of components using high-strength plastics or composites, reducing weight without compromising durability.

- Automated Feeding and Discharge Systems: Sensors and electronic controllers optimize material flow, ensuring consistent cement supply and minimizing waste.

- Modular Design: Enables easy assembly, disassembly, and customization for different project types and environments.

- Energy-Efficient Operation: Electronic controls optimize power consumption during startup and operation phases.

Advantages of Implementing Mobile Cement Silos in Construction Business

Adopting mobile cement silos offers a multitude of benefits, transforming traditional construction practices into modern, agile, and efficient workflows:

Increased Productivity

The ease of transport and rapid setup of mobile silos significantly reduces lead times. Construction sites can commence operations sooner and maintain a continuous supply of cement, which accelerates project timelines and reduces labor idle times.

Cost Savings and Return on Investment

While the initial investment in smart mobile silos may be higher, the long-term savings through reduced material wastage, decreased labor costs, and minimized downtime are substantial. Automated systems optimize resource utilization, translating into tangible financial benefits.

Enhanced Safety and Compliance

Real-time monitoring and automated controls reduce manual handling and exposure to hazardous materials. Additionally, integrated safety protocols ensure compliance with industry standards, fostering a safer work environment for personnel.

Environmental Benefits

Modern mobile silos with efficient electronic controls facilitate reduced energy consumption and waste minimization. Their lightweight, 3D-printed components contribute to sustainable manufacturing practices and lessen the operational carbon footprint.

Implementing Smart Mobile Cement Silos: Best Practices for Success

To maximize the benefits of mobile cement silos, construction firms and material suppliers should consider strategic implementation methodologies:

- Thorough Site Assessment: Evaluate site logistics, access routes, and environmental conditions to select appropriate silo models.

- Integration with Existing Supply Chains: Ensure seamless compatibility with other machinery, transportation logistics, and inventory management systems.

- Training and Support: Equip personnel with comprehensive training on electronic controls, maintenance protocols, and safety procedures.

- Regular Maintenance and Data Analysis: Leverage IoT data insights for predictive maintenance and continuous process improvements.

- Customization and Modular Expansion: Utilize 3D printing capabilities to adapt silo components or expand systems as project demands evolve.

The Future of Business Innovation Through Technology-Driven Solutions

The synergy of electronics and 3D printing is driving an era of unprecedented innovation in diverse industries. For the construction sector, mobile cement silos embody this transformative wave by offering solutions that are smarter, more efficient, and highly adaptable. These advancements are not only revolutionizing material handling but also elevating safety standards, reducing environmental impact, and boosting overall project profitability.

Leading companies like polygonmach.com are at the forefront of this technological revolution, providing state-of-the-art equipment and solutions tailored to meet the demands of modern construction and manufacturing. As these technologies continue to mature, their integration into daily operations will become indispensable for any business aiming to stay competitive and innovative.

Conclusion: Embracing Technological Advancements for Long-Term Business Growth

Innovations such as mobile cement silos powered by advanced electronics and 3D printing are shaping the future landscape of construction and industrial operations. Businesses that adopt these cutting-edge solutions stand to gain significant advantages in efficiency, safety, sustainability, and profitability. The key to successful integration lies in strategic planning, continuous learning, and leveraging the latest technological innovations to streamline processes and reduce operational costs.

By staying ahead of technological trends and investing in smart, versatile equipment, companies can not only improve their current workflows but also prepare themselves for the challenges and opportunities of tomorrow’s business environment. The era of digital transformation has arrived, and embracing it is essential for sustained growth and competitive excellence.