Unlocking Business Success with Cutting-Edge Label Printer Applicator Technologies

In today's fast-paced commercial landscape, the ability to produce precise, efficient, and scalable labeling solutions is critical for ensuring operational excellence. The label printer applicator represents a technological marvel in the realm of printing services, electronics manufacturing, and computer hardware. Companies like Omega Brand have pioneered the integration of advanced label printer applicator systems that revolutionize workflows, improve accuracy, and reduce costs.

Understanding the Role of a Label Printer Applicator in Modern Business

The label printer applicator is an innovative device that combines precision printing and automatic label application into one seamless process. It plays a pivotal role in automating manufacturing, packaging, and shipping operations by delivering consistent labeling with minimal manual intervention. As businesses expand and demand higher efficiency, the importance of reliable label printer applicator systems cannot be overstated.

Why Every Business in Printing Services, Electronics, and Computers Needs a Label Printer Applicator

Investing in a label printer applicator offers numerous advantages that solidify its importance across various industries:

- Enhanced Efficiency: Automates the labeling process, reducing cycle times and increasing throughput.

- Improved Accuracy: Ensures each label is correctly positioned and printed with high precision, minimizing errors.

- Cost Savings: Decreases labor costs and waste, leading to significant savings over manual processes.

- Scalability: Adaptable to various production scales, from small batch runs to high-volume operations.

- Quality Control: Supports high-quality printing with consistent output, essential for brand reputation and regulatory compliance.

Applications of Label Printer Applicator in Key Industries

1. Printing Services Industry

In the printing services sector, the label printer applicator elevates businesses by allowing rapid customization and high-resolution label production. Whether for personalized product labels, promotional materials, or bulk printing, these systems provide versatility and reliability. Their ability to integrate with digital printing workflows ensures seamless operation and rapid turnaround times.

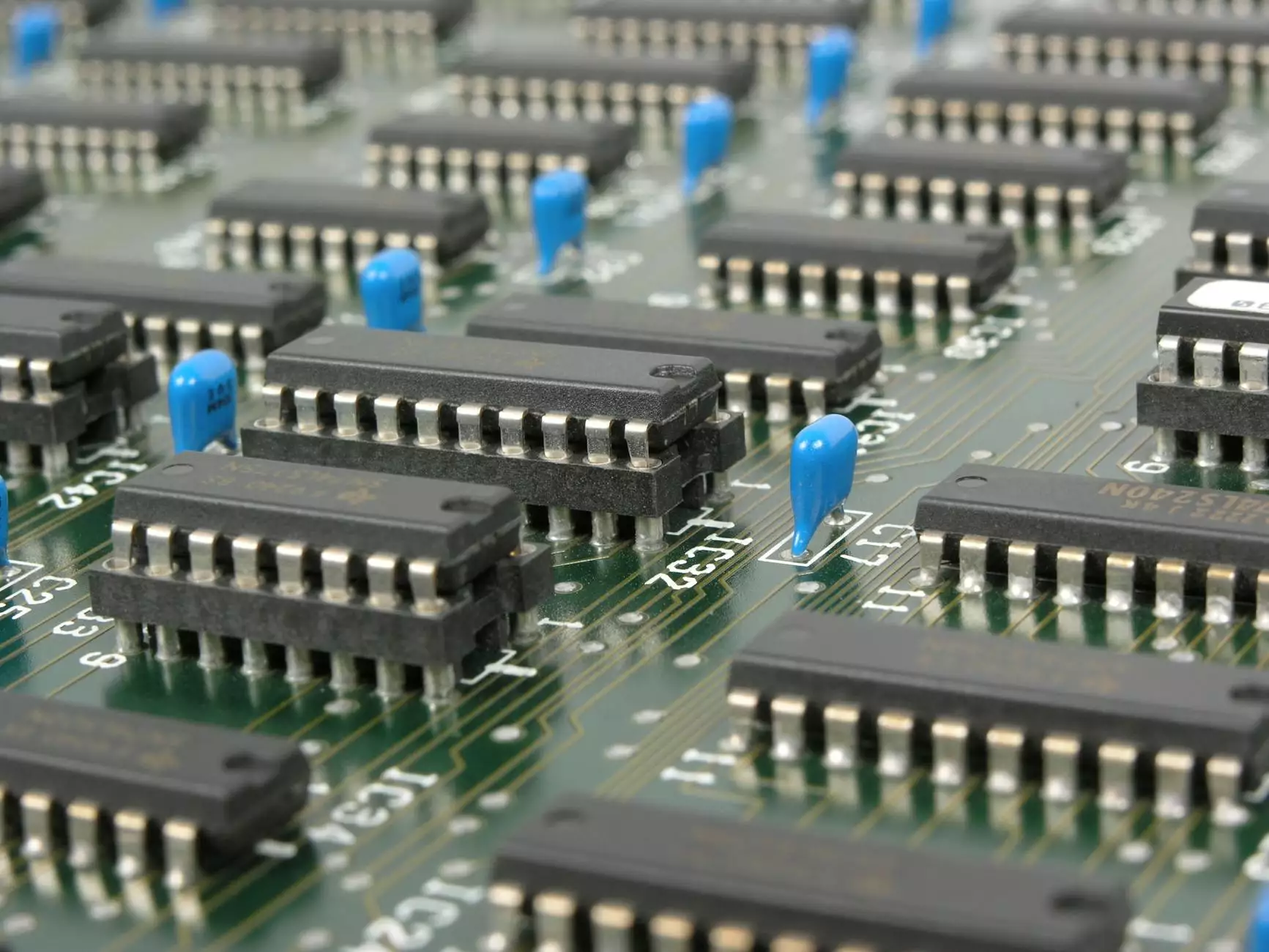

2. Electronics Manufacturing

Electronics manufacturing relies heavily on precise labeling for component identification, safety warnings, and certification marks. The label printer applicator facilitates high-speed labeling of circuit boards, components, and final products. Its accuracy helps maintain compliance with international standards, minimizes errors, and supports traceability efforts vital for quality assurance.

3. Computer Hardware and IT Infrastructure

Within the realm of computers and IT infrastructure, proper labeling ensures easy identification of accessories, servers, and network components. The label printer applicator allows IT departments to create durable, clear labels that withstand operational stresses, reducing misconfiguration and downtime. Efficient labeling workflows also streamline inventory management and asset tracking.

Key Features of Leading Label Printer Applicator Systems

Modern label printer applicator machines incorporate a variety of features tailored to meet the diverse needs of industries. Notable features include:

- High-Resolution Printing: Ensures sharp, legible labels with detailed graphics and small fonts.

- Automatic Label Application: Precisely places labels in designated spots without manual handling.

- Compatibility with Various Label Types: Supports different label materials, sizes, and adhesives.

- Intuitive User Interface: Touchscreen controllers and software integrations simplify operation and configuration.

- Integration Capabilities: Compatible with existing manufacturing and inventory management systems for streamlined automation.

- Durability & Resistance: Designed to withstand harsh environments, ensuring labels remain intact under various conditions.

Choosing the Right Label Printer Applicator for Your Business

Selecting an optimal label printer applicator involves evaluating specific business needs, production volume, and budget. Consider the following factors:

- Production Capacity: Determine the volume of labels required daily or weekly.

- Label Specifications: Assess the sizes, materials, and adhesive types needed for your products.

- Operational Environment: Choose machines that can operate efficiently in your workspace’s temperature, humidity, and cleanliness levels.

- Integration Compatibility: Ensure seamless connection with existing software and machinery.

- Ease of Use & Maintenance: Opt for systems with user-friendly interfaces and minimal maintenance requirements.

- Cost and Return on Investment: Balance initial costs with long-term gains in efficiency and quality improvements.

Future Trends and Innovations in Label Printer Applicator Technology

The future of label printer applicator technology is dynamic, driven by advancements in automation, artificial intelligence, and connectivity. Emerging trends include:

- Smart Labeling Systems: Incorporating AI to optimize label placement, detect errors, and adapt to changing production demands.

- Integration with IoT: Real-time monitoring of machine performance and maintenance needs to prevent downtime.

- Eco-Friendly Materials: Supporting sustainable labeling options that minimize environmental impact.

- Enhanced Data Management: Streamlined data collection for traceability, regulatory compliance, and analytics.

- Customization at Scale: Rapidly producing personalized labels for marketing or regulatory purposes.

Conclusion: Elevate Your Business with the Right Label Printer Applicator

In the competitive worlds of printing services, electronics, and computer hardware, adopting cutting-edge label printer applicator technology is a strategic move toward operational excellence. These systems offer unmatched precision, speed, and reliability, enabling businesses to meet market demands efficiently while maintaining the highest quality standards.

At Omega Brand, we specialize in providing innovative printing solutions that cater to your specific industry needs. Our range of label printer applicator systems integrates seamlessly with your production line, ensuring productivity gains and cost reductions.

Investing in a high-quality label printer applicator today positions your business for future growth, enhanced brand reputation, and operational resilience. Discover more about our advanced solutions and how we can help propel your enterprise to new heights.