The Essential Guide to Parts Crankshaft: Understanding Their Role in Diesel Engines

In the intricate world of diesel engines, one component stands out for its vital function: the crankshaft. It forms the heart of the engine, converting linear motion into rotational motion, enabling the vehicle to operate smoothly and efficiently. Understanding the complex workings and the significant influence of quality parts crankshaft can empower businesses and enthusiasts alike. This article aims to provide a detailed insight into the importance of crankshaft components, their applications, and how to source the best parts in the market.

The Importance of the Crankshaft in Diesel Engines

The crankshaft is not merely a metal rod; it is a finely engineered mechanism that has many critical responsibilities:

- Conversion of Energy: The primary role of the crankshaft is to convert the energy produced by combustion into mechanical energy that powers the vehicle.

- Maintaining Engine Balance: A well-balanced crankshaft reduces vibrations, ensuring a smoother operation and prolonging the lifespan of the engine.

- Distributing Power: The crankshaft efficiently transmits power throughout the engine, affecting other critical components like camshafts and drive belts.

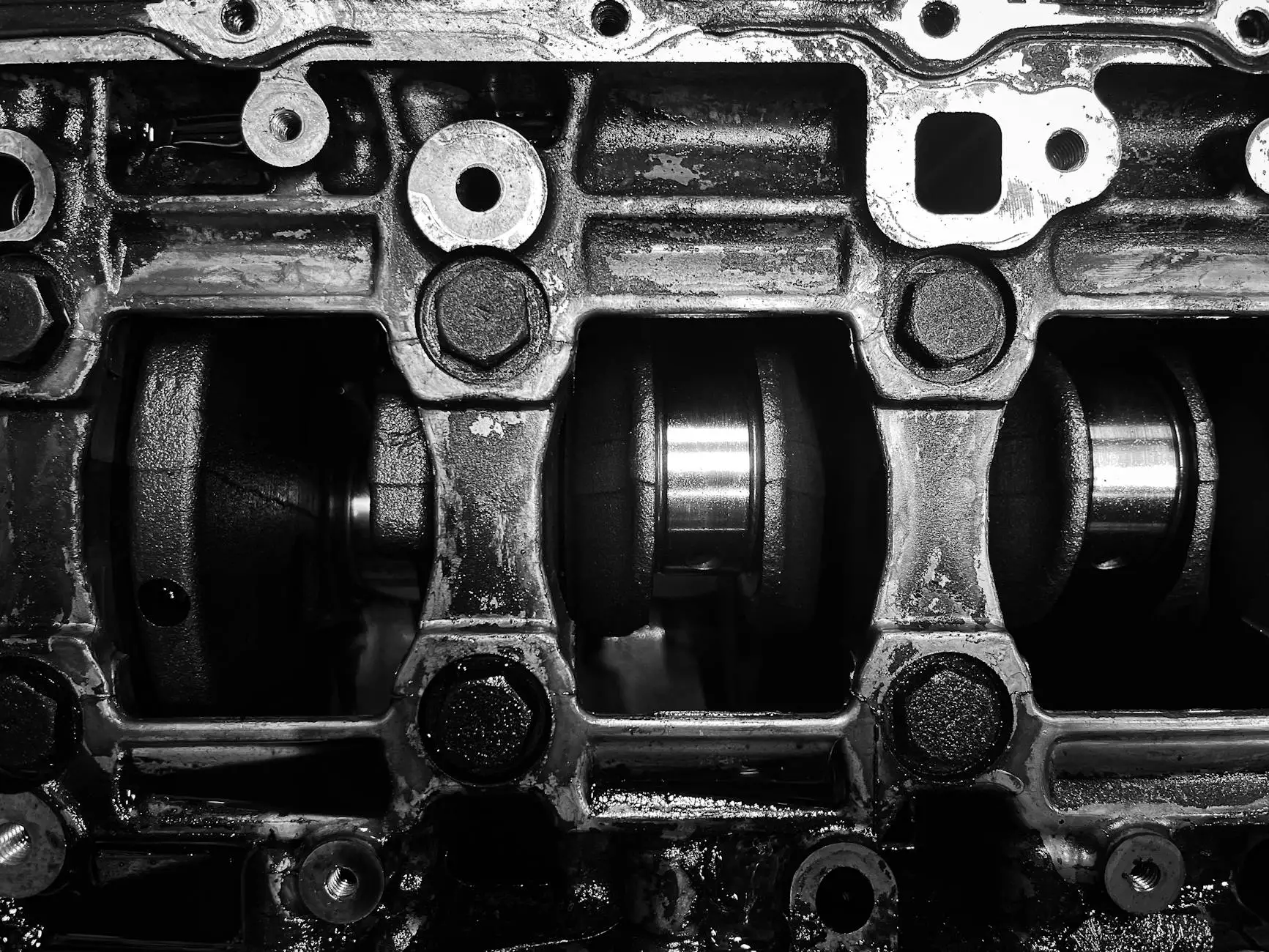

Understanding the Construction of the Crankshaft

The construction of a crankshaft is intricate, and it involves several key parts:

- Crankpins: These are the cylindrical projections that connect the crankshaft to the connecting rods.

- Main Journals: They provide support and guide the motion of the crankshaft.

- Counterweights: Essential for balancing the crankshaft, counterweights help reduce vibration caused by the reciprocating action of the crankpins.

- Flywheel: Although not part of the crankshaft itself, the flywheel connects to it, storing energy created by the engine's cycles.

Types of Crankshaft Parts

Different diesel engines require different types of parts crankshaft, depending on their design and performance requirements. Here are some common types:

- Forged Crankshafts: These are known for their strength and durability, often used in high-performance engines.

- Cast Crankshafts: Generally more affordable, cast crankshafts are common in standard diesel engines.

- Stroker Crankshafts: Designed to increase the engine's displacement, stroker crankshafts can enhance power output significantly.

Why Quality Matters in Parts Crankshaft

When it comes to components like the crankshaft, quality cannot be compromised. Here are several reasons why sourcing high-quality parts crankshaft is non-negotiable:

- Performance: Quality parts enhance the overall performance of the engine, leading to better fuel efficiency and power output.

- Longevity: High-quality materials resist wear and tear, extending the life of the crankshaft and, consequently, the entire engine.

- Safety: A failure in the crankshaft can lead to catastrophic engine damage, making the selection of reliable parts critical for safety.

Key Materials Used in Crankshaft Manufacturing

The materials used in manufacturing crankshafts play a significant role in their quality and performance. Key materials include:

- Alloy Steel: Known for its high strength and resistance to fatigue, alloy steel is a popular choice for high-performance crankshafts.

- Cast Iron: Strong and durable, cast iron is often used in standard crankshaft applications.

- High Carbon Steel: This material is favored for its excellent wear resistance capabilities, making it suitable for heavy-duty engines.

How to Choose the Right Parts Crankshaft Suppliers

Finding the right supplier for parts crankshaft is crucial for ensuring quality and performance. Here are some tips to help in the selection process:

- Reputation: Research the supplier's reputation within the industry. Look for reviews and testimonials from previous clients.

- Quality Certifications: Ensure that the supplier adheres to stringent quality standards and possesses relevant certifications.

- Range of Products: A supplier who offers a diverse range of crankshaft parts can provide better options to suit specific engine needs.

- Customer Support: Choose a supplier that offers excellent customer service and support for any inquiries or issues that may arise.

Understanding Crankshaft Maintenance

Once you have installed quality parts crankshaft, maintaining them is essential for ensuring longevity and performance. Here are some maintenance tips:

- Regular Inspections: Conduct regular checks for wear, damage, or misalignment, which can significantly impact performance.

- Lubrication: Ensure proper lubrication to reduce friction and prevent premature wear.

- Monitoring Engine Performance: Keep an eye on engine noises, vibrations, and overall performance. Any abnormalities could indicate an issue with the crankshaft or associated parts.

Emerging Technologies in Crankshaft Manufacturing

The field of crankshaft manufacturing is evolving rapidly due to advancements in technology. Here are some emerging trends:

- 3D Printing: This technology is being explored for producing complex crankshaft designs that traditional manufacturing methods cannot achieve.

- Computer-Aided Design (CAD): CAD software is transforming how crankshafts are designed, allowing for precise engineering and optimization.

- Use of Composite Materials: Research is underway to explore the feasibility of composite materials that could offer improved performance characteristics while reducing weight.

Conclusion: Investing in Quality Parts Crankshaft

In summary, parts crankshaft play an indispensable role in the operation of diesel engines. Their importance cannot be overstated, as they are central to converting energy within the engine, ensuring proper function, and greatly influencing performance. Investing in high-quality crankshaft parts from reputable suppliers like client-diesel.com is essential for maximizing engine performance and longevity. By understanding the complexities of these parts, businesses can make informed decisions that lead to successful operations and satisfied customers.

Final Thoughts

As diesel engines continue to power various industries, understanding components such as the crankshaft becomes increasingly vital. Whether you're a business owner sourcing parts for maintenance or an enthusiast looking to upgrade your diesel engine, the value of quality parts crankshaft cannot be ignored. Make informed choices, prioritize reliable suppliers, and ensure that your engines run smoothly and effectively.